Developing & Bringing New Products to Market

Part 1: No Compromises, A Better Mouse Trap. Really?

by John Neugent

Tech articles | Commentary articles | Product Development series part 2

John Neugent probably knows more about bicycle wheels than anyone else alive. Maybe more about bikes as well. He's spent his life in the bike business, at every level. He now owns Neugent Cycling, a firm devoted to delivering world-class equipment at the lowest possible price. If you are in the market for a set of wheels, please, check out John's site. He really knows his stuff. —Chairman Bill

John Neugent

Bill and Carol McGann's book The Story of the Giro d'Italia, A Year-by-Year History of the Tour of Italy, Vol 1: 1909 - 1970 is available as an audiobook here. For the print and Kindle eBook versions, just click on the Amazon link on the right.

John Neugent writes:

One common comment you see in marketing is “We make no compromises!” Yet everyone knows, if you develop a product, compromise is the key to success. Ralph Waldo Emerson’s saying of “make a better mouse trap and the world will beat a path to your door” is about on the same level. Both are misconceptions of reality.

Compromise is, in fact, either the key or one of the key components of any new product. You have to compromise on materials, vendors, tolerances, designs, and many other issues. If everything appears to be to your specifications and the vendor can’t make enough, your sales will be limited to his production capacity. All the pieces have to fit so often there are compromises on many different issues because there is no other choice.

Timing is often a major issue. Let’s say for example, you want to make a new bicycle hub. Bicycle hubs are typically made by companies that source almost all of the component parts. In Taiwan, hub shells are forged so you need a forger. Axles, end caps, pawls, springs are also outsourced. The hub maker typically machines the hub shell from the forging and assembles the parts so in reality you are typically buying from four or five manufacturers any one of whom has the potential to make either a bad part of not deliver on time. Each also have manufacturing capabilities. Any one vendor can affect your timing.

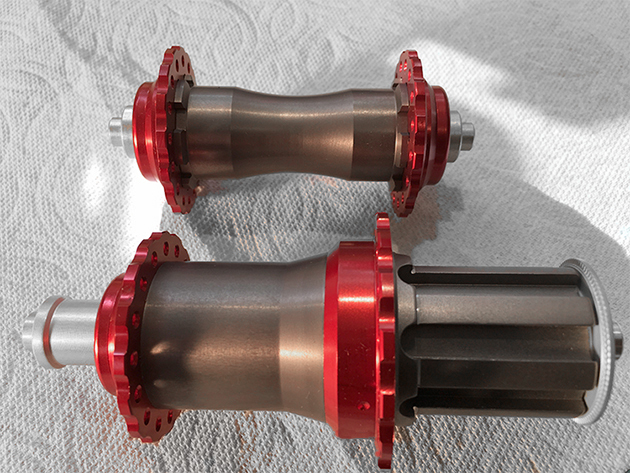

Getting a product to this point, ready to use, is a complex process. Photo courtesy South Salem Cycleworks.

Another major factor is design tolerances. In a hub, in particular, there are stack tolerances. These occur when you have parts “stacked” on each other. In the case of the hub, you have a fixed axle with four bearings. One bearing goes into each the drive and non-drive-side hub shell and the other two engage the cassette body so the tolerances in the hub shell and cassette body effective multiply themselves. If you have ever seen sprockets appear to wobble when you spin the wheel and hold the sprockets you see this in action. So there is a compromise you have to make to determine how much wobble is acceptable.

With regard to building a better mouse trap, that may have been true in Emerson’s time, but the world has changed. I make and have sold thousands of wheels over the last 20 years and while it’s critical that I have a good product for a fair price, the success of the company is based on the marketing. No one beats a path to your door anymore – outside of a lucky viral introduction. You need to generate sales with a sound marketing program.

So the next time you see a company saying the make no compromises, or hear the mouse trap comment treat them with a large grain of salt.

John Neugent was was one of the first to establish quality hand building in Taiwan around the turn of the century. He now owns Neugent Cycling, a firm devoted to delivering world-class equipment at the lowest possible price.

.