A recent history of spokes

by John Neugent

Tech articles | Commentary articles

John Neugent probably knows more about bicycle wheels than anyone else alive. Maybe more about bikes as well. He's spent his life in the bike business, at every level. He now owns Neugent Cycling, a firm devoted to delivering world-class equipment at the lowest possible price. If you are in the market for a set of wheels, please, check out John's site. He really knows his stuff. —Chairman Bill

John Neugent

Stoic philosopher Epictetus' Golden Sayings is available in both audiobook & Kindle eBook versions. To get your copy, just click on the Amazon link on the right.

John Neugent writes:

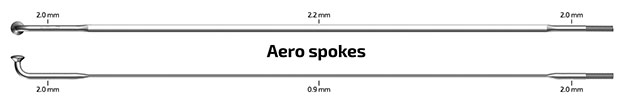

Most people don’t really think about spokes. Unless, of course, you’re a spoke sniffer, a term I did not coin but applies to me. I am only mentioning steel spokes since they are by far the most common. One of Sapim’s CX-Ray spokes and alloy nipple will set you back $4.50. If you have 44 of them, it’s almost $200. Why do they cost so much?

To understand it you need to understand how wheel “systems” work. Of course you know wheels are essentially suspension systems that use spokes under tension. Stainless steel spokes, which are used in all quality steel spoked wheels, are forged from wire. All the top brands have their own special formula but they are similar. Spokes don’t fail by ultimate stress overload, but by fatigue. The more cycles of fatigue, the shorter their life. And they come out of the box with some built in areas of stress.

CX-Ray spokes

I am not an engineer and any engineer reading this will probably know I am at best stumbling around here, but I think I get to bottom line as well as anyone. One does not need to be a great chef to appreciate good food and even an ant knows a tasty meal when it finds one.

When one builds a high quality wheel, it’s important to stress the spokes past their yield point. For us with engineering brains of ants, the yield point is where the spokes lose their elasticity and become “plastic” for lack of a better work. A wheel builder does this by stressing the spokes after the wheel is built. I’ve seen many ways of doing this and most do nothing, but I am not going to divulge my secret method that is far superior to anyone else here. But in general you stretch them past their yield point. People with children know how easy this is to do on a bad day and the method is similar.

So the bottom line, as I am sure you now realize is the trick is to make spokes with fewer stress points so they have already yielded – so to speak. If fatigue is the result of stress points and you eliminate them you make a spokes with longer life and this is really the magic and why you are paying $4.50 for a piece of steel that should, you believe, cost a quarter. They have eliminated ways to eliminate stress points, but what’s the point?

In the dark ages when I was growing up, wheels had 36 spokes or maybe 32 for racers. Then Mavic invented the wheel system in the mid ‘80s and introduced wheels with lots fewer spokes – 20 in the front and 24 in the rear, and other wheel companies had even less. Spokes not only add weight but also are egg beaters in the wind so reducing the number quickly added to performance. It took spokes a long time to catch up so that they were durable enough to meet the new requirements.

Mavic pointed the way towards ultra-low spoke count wheels. Photo: South Salem Cycleworks.

Spokes used to break at the bend. I’ve seen less than 10 do that in the 20 years I have been building wheels. Then spokes changed. The top spoke makers don’t let you see where they make their magic of doing double butting and blading but rumor has it that it’s a specific forging system (think of micro hammers hitting thousands of hits per second and you will probably be as wrong as I am).

At the end of the day I really don’t care. But I do marvel at a 4-gram spoke with 43 of its mates supporting the strongest riders in the world.

John Neugent was was one of the first to establish quality hand building in Taiwan around the turn of the century. He now owns Neugent Cycling, a firm devoted to delivering world-class equipment at the lowest possible price.