Which Wheels Are Best For You?

by John Neugent

Tech articles | Commentary articles

John Neugent probably knows more about bicycle wheels than anyone else alive. Maybe more about bikes as well. He's spent his life in the bike business, at every level. He now owns Neugent Cycling, a firm devoted to delivering world-class equipment at the lowest possible price. If you are in the market for a set of wheels, please, check out John's site. He really knows his stuff. —Chairman Bill

John Neugent

Les Woodland's book Cycling’s 50 Craziest Stories is available as an audiobook here. For the print and Kindle eBook versions, just click on the Amazon link on the right.

John Neugent writes:

Deciding which wheels are best for your type of riding can be confusing. The purpose of this article is to give you a path to follow. The most important issues are your budget, the type of riding, and to a lesser extent, your weight.

Budget: It may be surprising to many people that you can get some very good wheels for $200. Particularly if you get used wheels, but be careful when purchasing used wheels. Wheels wear out and maybe just as importantly, the technology is continually changing. So if you are using an 11-speed drive train, getting wheels that will only accept 10 won’t work. Also, on lower spoke count wheels (28 for the rear, or 20 or less for the front) the first sign of wear is usually rim cracks. In particular, on the drive side rear spokes. Look for tiny lines radiating from the spoke holes. People often ride wheels with rim cracks without knowing it.

If you want a top-name brand with the latest technology you can spend thousands on a set of wheels but there are lots of great choices at lower prices.

Type of riding: Are you a serious racer, club rider, fast group rider, moderate speed rider, slow rider, hill climber, flatland rider, or touring rider? How hard are you on wheels?

Pro riders picking up their low spoke-count aerodynamic wheels that will be replaced as needed by a team with a multi-million Euro budget. Sirotti photo

I believe the most important factor on wheels is the rim and spoke count. The reason I say this is they both have a big influence on aerodynamics. The deeper the rim and the fewer the spokes, the more aerodynamic they are. Also, the first thing that normally wears out on wheels is the rim through rim cracks. The fewer the spokes the quicker this is going to happen.

For road riding, most people are fine with 24 spokes in the back and 20 or even 18 in the front. That’s generally what the top pros run and although they are not heavy, they are extremely powerful and put a lot of stress on wheels. For touring you would want to go with more spokes because you have a lot of weight on the wheels. I remember in the early ’70s there was a very strong and very heavy rider who wanted to go cross country and I built up a set with 13 gauge (2.2 mm vs 2.0 for normal spokes) spokes and drilled out the hub flange and rim to accept the bigger spokes and nipples. 36 front and rear – AKA tank wheels.

For people who average less than 15 mph, aerodynamics is not a major factor. For the go-fast people who average 17 mph or more on flat ground with no wind, aerodynamics is a big factor. Often as much as a gear difference for real fast people.

The deeper the rim, the more aerodynamic it is. Most of the top pros ride 50-60 mm deep rims for most riding. For someone averaging below 15 mph, a lighter alloy rim would probably be faster especially up hills.

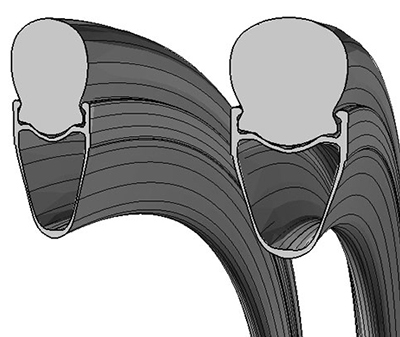

On the subject of rims, over the last 5 years or so, wider road-riding rims became popular because they hold more air, which gives you both better performance and more comfort. The reasons are the subject of another article. But it is important to be aware of it. The old standard was 19 mm wide external, the new ones are 22-28 external.

Newer wider rims (right) are becoming more popular.

Spokes are going to probably be the next most important thing on the wheels (note, I have not gotten to hubs yet). There are many types of spokes – steel, aluminum, carbon (pulltruded), etc… One key thing you need to know is that spokes break. All spokes break. Also, you typically spend a lot of money for any material other than steel (actually stainless steel). So for those two reasons I recommend stainless steel. There are a few really good spoke makers that almost everyone uses. Sapim, DT Swiss, and Pillar. Even some of the other wheel companies who have their own brand often use one of the three to make their spokes. Strangely, usually it’s the lighter of the stainless steel spokes that are the strongest. Spokes break through fatigue and the thinner ones can flex more. So a stainless spoke, properly made that is 2.0 - 1.5 double butted is stronger than a similar spoke 2.0 – 1.8. And they play a major role in wheel weight. The 2.0 - 1.5 spoke is about 4 grams and the 2.0 - 1.8 is about 6.5 grams. Multiply that times the number of spokes and it’s significant. And one must not forget the nipples. Brass nipples add almost 1 gram of weight per nipple and with the newer 7000 series alloy that nipple makers are using, the alloy nipples are virtually as strong as the brass, although brass nipples are better with regard to corrosion – normally not an issue unless you live or ride very near to the ocean.

Finally we are getting to the hubs. Most people think of hub quality as being the most important and 30 years ago it was, but a few things have changed that. Cartridge bearings were introduced by a couple of US hub makers in the early ’70s because they didn’t have the tooling to make cup and cone hubs. Cartridge bearings were relatively inexpensive and extremely good. The reason for this is they are made by the millions for all kinds of machines. During the manufacturing process they measure the “set” of ball bearings they are putting into each cartridge bearing to insure the best compatibility – this in a relatively inexpensive bearing. Cartridge bearings offer a number of advantages. They are very high in quality, inexpensive, and relatively easy to replace and when you replace the bearing you replace both the cup and cone.

One recent development has been ceramic bearings, which have been touted to do all kinds of incredible things. Unfortunately they do not. From a practical standpoint, the only performance advantage they offer is they use a light lubricant thereby allowing them to spin with less friction. The downside are their expense and lack of durability. Unless you get a completely ceramic bearing the ceramic bearing wears out the steel race and you could get a very nice set of wheels for the price of full ceramic bearing only.

How about the rest of the hub? Look at a hub and it’s a shell with bearings and spoke holes and an axle. The rear hub has a cassette which is a mini hub that engages the main hub to drive it. I could go into a lot more detail here, but essentially about 20 years ago, lower end bicycle component production was moving to China, away from Taiwan. The Taiwanese quickly understood their future was in making quality components. It takes time to do this because most makers (the Taiwanese word for manufacturers) use subcontractors for many of the components within their component. So a series of makers need to change. But change they did. Many of the Taiwanese makers started their own factories in China to make lower-end products and upgraded their Taiwanese factories for higher-end products.

I was fortunate enough to experience this when I set up high-end wheel building there in 2000. No one had ever heard of a tensiometer and most wheels were not even built by machines (Holland Mechanics), but by builders who the bulk of their building with, for lack of a better term, an electric screw driver. For me it was an education to see just how far they could get with their very rudimentary tools. They were and are craftsmen.

So back to the hub. You can get good, relatively inexpensive hubs for about 450 grams a set. Really good ones are in the 350 gram range (for the pair). The heavier hubs tend to be as durable or better than the lighter pair. Bearing quality is equally close because cartridge bearings are inexpensive. The hundred grams of weight difference you can easily make up for in the spokes and nipples and even rims.

Of course, this cuts out all of the marketing. I will leave it at that. I am a custom wheel builder so I need to put my two cents into the value of a custom build. If you have 32 or 36 spokes on a wheel, the wheel is so overbuilt with extra strength so you have no need for quality hand building. When you get to smaller spoke counts it makes a difference in terms of durability. The tighter the spoke the longer it takes to loosen. Loose spokes create movement and wear. The more equal the tension (something best achieved by hand building) the less likely the wheel will go out of true (less chance for brake pad rubbing).

It is not rocket science to build a great wheel, but it takes practice, and even though our wheel building is the equal to anyone, I still have a lot of respect to those Taiwanese builders who primarily used drills. Their market was different but they had the exact skills for their market. I had the honor to work with them to build higher end product.

John Neugent was was one of the first to establish quality hand building in Taiwan around the turn of the century. He now owns Neugent Cycling, a firm devoted to delivering world-class equipment at the lowest possible price.